CNC Engraving is one of the most interesting and artistic things you can do with a CNC. In this guide, you’re going to learn everything you need to know to tackle your own CNC engraving work.

- T2 Laser Registration Code

- T2 Laser Tutorial

- T2 Laser Serial Number Lookup

- T2 Laser Crack

- T2 Laser Serial Numbers

- T2 Laser Serial Number Search

The Autoreflex T2 / New FTA is available in chrome-black and black only, the chrome-black version is much more common. The Autoreflex T came with one of Konica’s legendary Hexanon prime lenses. The optical quality of most Hexanon lenses is regarded as truly superb, particularly the older fixed-focal length (prime) lenses, like this 52mm f/1.8.

What is CNC Engraving?

Laser Diodes: Very low end laser engravers use laser diodes and are typically less than 5 watts in power. In fact, 5w laser diodes are rare and most are much less. These lasers can’t do much at such low power levels, so they’re more a curiousity than anything. CO2 Gas Lasers: The most common type of laser in laser engraving machines is the. Inserts custom text fields (i.e., serial number, barcode) into job files Auto-Verify: Integrated vision interface module for grading, with remark on verification failure Auto Re. The Model and Serial number can be found on the bottom left side on the outside of your fridge. It is also located in the left side of the right compartment of your fridge. Top Mount Freezer. The Model and Serial number can be found on the bottom left side on the outside of your fridge. It is also located in the left side of the bottom. It's how we control the laser power. In T2Laser you can set the min and max levels to anything you like, but the standard firmware is 0-255 so that's what I recommend. If you want to use 0-1000 for example you can but you also need to change the Grbl parameter $30 to match the setting in T2Laser.

Engraving is the art of carving a design into a hard surface. Typically its done by hand, using an assortment of hand engraving tools:

Image via Wikipedia

This is a laborious and difficult to learn process. Fortunately, CNC machines are capable of very sophisticated engraving.

Sometimes CNC engraving is purely utilitarian, for example to add a serial number to a part. Other times it is an artistic embellishment. The type of CNC Engraving Machine you have will determine most of what’s needed to engrave.

CNC Engraving Machines

CNC Engraving is typically done either by a laser or by a rotating tool in a milling machine or CNC Router.

Laser Engravers and Machines

Image courtesy of Epilog Laser…

T2 Laser Registration Code

Lasers can be used to engrave in two ways. First, if the laser engraver is powerful enough, it can cut the material. Second, even if it isn’t powerful enough to cut the material, it can discolor it in a visually distinctive way using a process called Laser Marking.

In many ways, laser engravers can be simpler than machines that use rotating cutters. The reason is a simple XY position will suffice–no Z axis is necessary with the laser.

They also have the great advantage that the laser beam imports no force to the workpiece, so workholding is not an issue. Often the workpiece just rests on the laser machine’s table without anything but gravity holding it there.

Materials that can be engraved

Many materials can be cnc engraved by laser including:

- Wood: The laser carbonizes or burns many natural materials like wood and leather.

- Leather

- Plastic

- Metals: Metal requires a lot more power and sometimes specific laser types that operate a frequencies that work more efficiently with metal.

- Coated Materials: Sometimes it’s easier to engrave with a laser that burns away or discolors a particular coating. There are specialty coatings made for exactly this purpose.

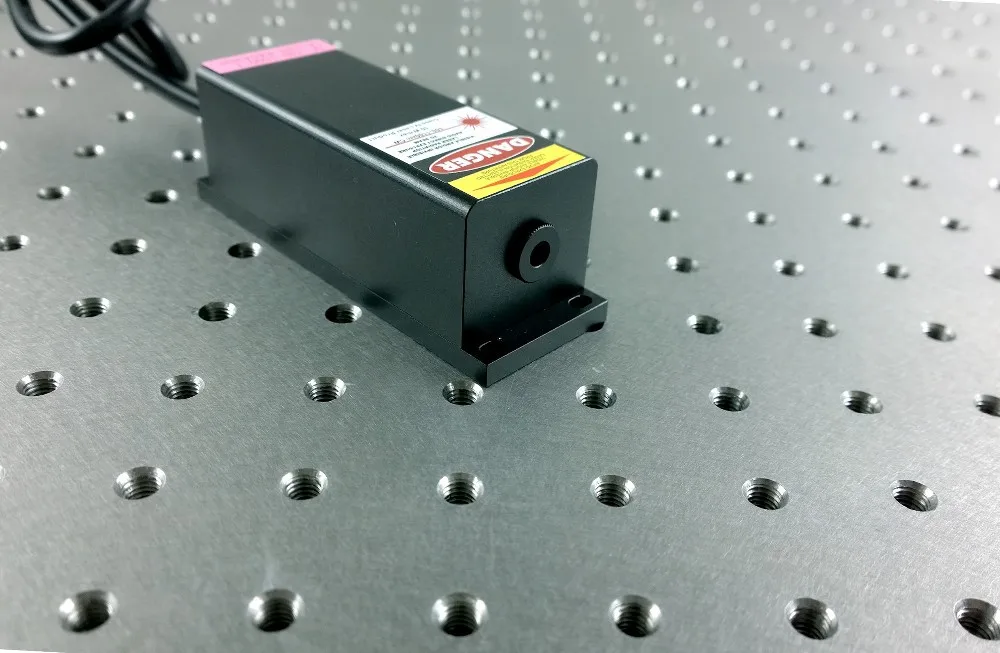

Common Laser Types

| Laser Diodes | Very low end laser engravers use laser diodes and are typically less than 5 watts in power. In fact, 5w laser diodes are rare and most are much less. These lasers can’t do much at such low power levels, so they’re more a curiousity than anything. |

| CO2 Gas Lasers | The most common type of laser in laser engraving machines is the CO2 Laser. These layers use a tube filled with CO2 (carbon dioxide) gas. They have very high efficiency and beam quality, plus they’re fairly cheap. That’s why they’re so common. They’re best suited for processing non-metallic materials. CO2 laser engravers have gotten quite inexpensive and commonly available. You can pick up a 40W laser engraving machine from Amazon for a little over $400. |

| Fiber Lasers | Fiber lasers are solid state lasers that work by generating a “seed” laser beam and then amplifying it in specially designed glass fibers. They produce a beam that’s 100x more concentrated than a CO2 laser, which makes them ideal for metal applications. They’re also good for plastics. |

| Crystal Lasers | Crystal Lasers are pretty similar to Fiber Lasers from an application standpoint. |

Laser Power Requirements

The amount of power required for a laser depends on the mateirial and the desired operation.

For example, when cutting materials like wood and plastic, consider the following guidelines for cutting:

- 1/8″ thick requires 30w

- 1/4″ thick requires 40w

- 3/8″ thick requires 50 to 60w

- 1/2″ thick requires 75 to 120w

These are rough estimates. You can use a lower powered laser to cut any thickness, but it requires more than the single pass these estimates assume.

The issue of choosing the proper laser power can be complex, so consult the manufacturer’s representatives to see what will work best for your application.

Smoke and Toxic Fumes from Laser Cutters and Engravers

T2 Laser Tutorial

Lasers work by heating the material they’re cutting or marking. When cutting the material is typically vaporized or turned completely into gas by the heat of the laser.

Most materials will produce smoke and sometimes toxic fumes when this is done. Consequently, it is often important to provide positive ventilation to carry the fumes outside via blower.

Mill and Mini CNC Engraving Machines

Any CNC Milling Machine can be used as a CNC Engraving Machine. Some are better at it than others.

One of the issues that will determine how good a CNC Machine is for engraving is the maximum spindle speed. Engraving Tools tend to be quite small in diameter and a lot of the materials being engraved are quite soft.

T2 Laser Serial Number Lookup

Both small diameter and softer materials leads to higher spindle speed requirements for cnc engraving.

If your milling machine lacks a high speed spindle, you may find it’s worthwhile to add a sub-spindle if you do a lot of cnc engraving work.

Bosch Colt Router attached as a high speed sub-spindle…

Here are a couple of articles about that:

- Austin Barnett’s Awesome Custom CNC Car Badges: Austin attached a trim router as a high-speed sub-spindle to his Bridgeport CNC Mill.

- High Speed Secondary Spindle: A scrapbook of high speed sub-spindle projects others have fabricated.

- Easy Multiple Spindle Options in G-Wizard: This article tells how a $400 sub-spindle made a job finish 6x faster. Quite an improvement!

Router Engraving

CNC Routers can be great engraving machines. Typically they have a large bed, and they’re fitted with a high speed spindle.

Engraving Tools: V-Bits, Drag Engravers, and Such

The typical cutting tools used for cnc engraving are V-Bits, small Ballnose End Mills, and Drag Engravers:

Floating Tool Holders for Engraving

Engraving can be very sensitive to surfaces that are not completely flat. You could just surface the area to be engraved with a fly cutter before the engraving process. But, another way to compensate is to use a floating tool holder for cnc engraving:

CNC Engraving Examples & Resources

Engrave on an irregular surface using special software to “warp” your g-code.

Like what you read on CNCCookbook?

Join 100,000+ CNC'ers! Get our latest blog posts delivered straight to your email inbox once a week for free. Plus, we’ll give you access to some great CNC reference materials including:

T2 Laser Crack

- Our Big List of over 200 CNC Tips and Techniques

- Our Free GCode Programming Basics Course

- And more!

Just enter your name and email address below:

100% Privacy: We will never Spam you!More articles you may like:

LightBurn talks directly to your laser, without the use of additional software.

We currently support most Ruida, Trocen, TopWisdom, and GCode based controllers. Supported GCode controllers,include Grbl, Smoothieware, Grbl-LPC, and Marlin. Supported Ruida controllers include the RDC6442G/S, RDC6445G, RDC6332G, RDLC-320A, and R5-DSP. Supported Trocen controllers include the AWC708C, AWC608, and TL-3120. More controllers will be added soon, so if you don't see yours listed, send us a message - maybe we're already working on it!

T2 Laser Serial Numbers

If your controller is GCode, Ruida, Trocen, or TopWisdom based, even if it's not listed it might be supported already - Download the free trial and try it for yourself. If it doesn't work, sometimes it only takes a day or two to make the required changes to support a new board in these existing families.

T2 Laser Serial Number Search

Please note that LightBurn does not support the stock M2-Nano board in the popular K40 laser. This board does not offer control of power through software - we recommend upgrading the board to take full advantage of LightBurn.